CAPA software

»CAPA Management — Corrective And Preventive Actions«

Software for your CAPA processes

Control your production-related QM processes such as corrective and preventive actions (CAPA) with our digital workflows. Our integrated solutions manage your previously paper-bound process from capture to completion completely digitally. The workflow system automatically forwards the digital form to the next instance; if deadlines are exceeded, the reminder and escalation management takes effect. Of course, an absence management is also included for the task routing.

How can you benefit from the CAPA software?

Process safety

After each step, the workflow system ensures that the CAPA is forwarded to the person in charge. The escalation system takes effect in case of missed deadlines.

Data integrity

Corrective and preventive actions (CAPAs) are no longer lost because they are stored digitally from the beginning. You also protect your data from unwanted interference of unauthorized users and from destructive forces.

Constant availability

Access your data at any time. It does not matter where you are.

Central information platform

Use d.velop documents (formerly d.3ecm) as your central information platform on which you can retrieve all your data at short notice.

Traceability

CAPAs can be linked to other modules such as Change Control. Thus a traceable chain of interrelated individual processes is created. CAPAs can be initiated, for example, from deviation reports or can initiate a change process.

Transparency

Every authorized employee sees the current status of all CAPA processes – even if he or she is not involved in the process.

Individual configuration

Let the modules be configured according to your wishes and preferences to facilitate the onboarding training for your colleagues.

Reports

Create reports and statistics about your CAPAs.

Get a first overview.

The digital forms are also converted to a PDF/A in parallel. This way, employees who are not involved in the process can also gain insight into the workflow and the document can be shared with external parties if required.

What is a CAPA process?

The CAPA process (Corrective and Preventive Action) allows drug safety errors/deviations to be systematically recorded and processed in conformity with regulatory and internal specifications. In the process, CAPA management focuses on the elimination of nonconformities (corrective action) and the avoidance of potential nonconformities (preventive action).

Nonconformities follow, for example, from a process deviation that results in certain corrective actions that can eliminate the existing problem.

For example, a preventive measure could result from an OOT analysis. No actual nonconformity has occurred here yet, but a degradation of the validated process has been noted.

The CAPA process can thus ensure continuous product quality.

Every action in the process is automatically documented by the system accordingly. Integrated audit trail functions ensure high traceability.

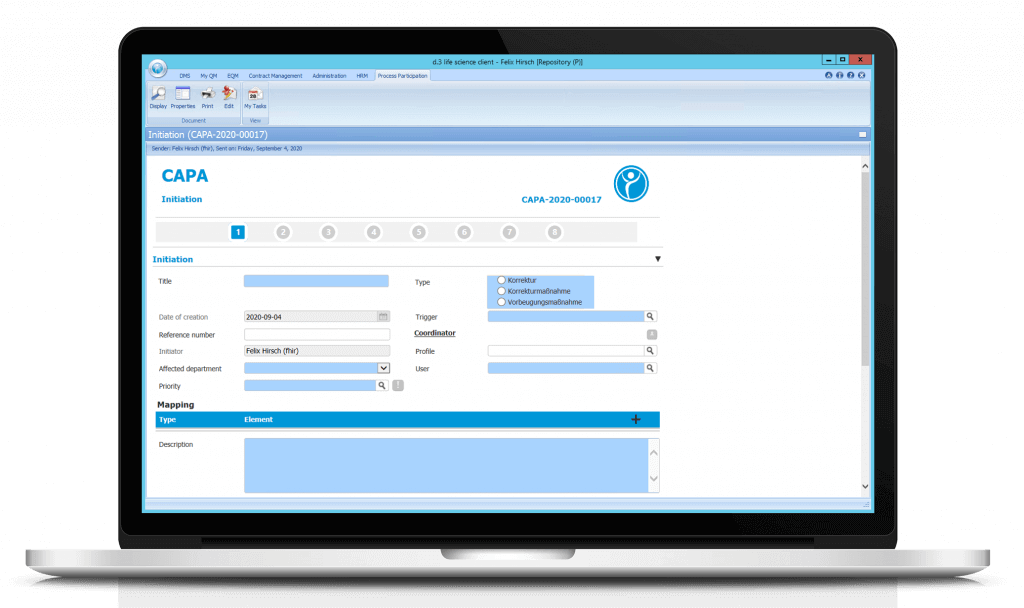

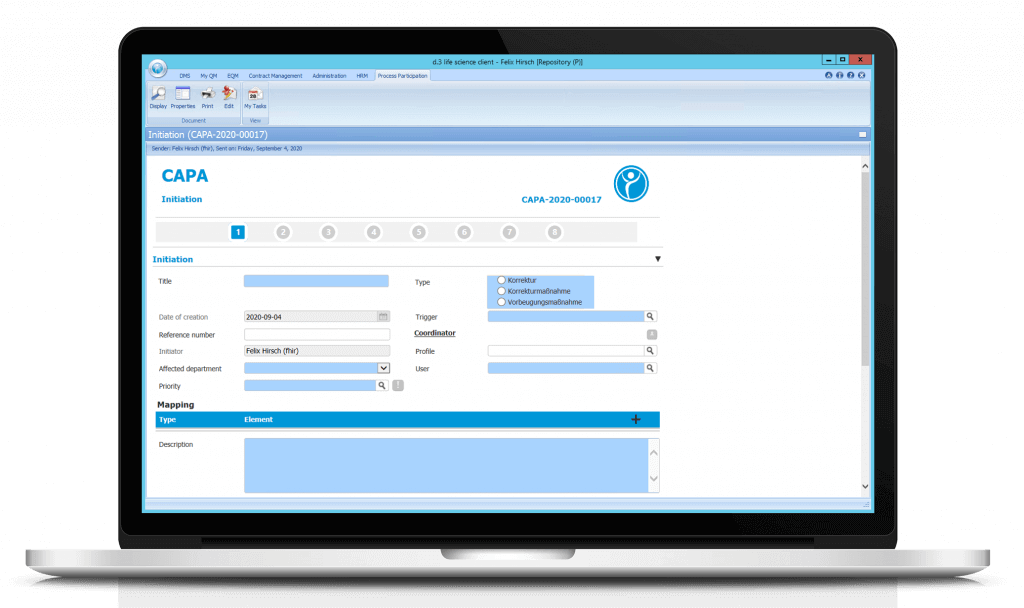

The digital form is filled out step by step and provided with the relevant entries and data. Fields with a blue background are mandatory. Predefined value sets and drop-down functions make it easy for users to fill out the form.

After processing the individual steps (1. Initiation, 2. Recording of measures and risks, 3. Expert committee, etc.), the workflow system automatically sends tasks and messages to the responsible agents or workflow participants. Once all steps have been processed, the workflow is considered complete.

1st Step: Initiation

The initiation of the CAPA is done by the process responsible of the concerned department. He or she records the relevant data for CAPA. The process is then forwarded to the appointed CAPA responsible.

Would you like a live insight into the software?

Get a live insight into the possibilities of the production-related QM processes in just 45 minutes with a sample use case. Learn how you can use the solutions of Digital Life Sciences to optimize your production-related QM processes such as complaints (Complaint), deviation reports (Deviation Control), corrective and preventive actions (CAPA) or change controls (Change Control) with our digital workflows.

Features of the Corrective And Preventive Actions software

- Automatic classification of the deviation based on the metadata entered in the form

- Referencing master data from your ERP system

- Integrated absence management

- Initiation of the individual tasks for the further processing of the workflow

- Adding documents, such as digital photos, to your CAPA form

- Initiation of a document change request for a controlled document

- Escalation messages both within the system and by e‑mail

- Automatic PDF creation and storage of the form in the eDMS after each step

Regulatory requirements in the CAPA process

- ISO 9001:2015, Chapter 8

- ISO 13485:2016, Chapter 8

- EU GMP Guide Part 1, Chapter 8

33 Good reasons for a cooperation with Digital LS

You’re not convinced yet? Find out about 33 good reasons speaking for a cooperation with Digital Life Sciences GmbH. We will show you reasons from the provider’s point of view, from the software point of view and other general reasons that distinguish us.

Customer review on the CAPA Management

“With the project staff of Digital Life Sciences a rapid implementation of the new DMS was possible in only three months. The modular structure of the system additionally allows a coordinated step-by-step expansion of the scope. The software was quickly accepted by all employees due to its clear design, which not only simplified the processes and release cycles in a very short time, but also improved their quality.”

You might also like…

The CAPA is a component of the Digital Life Sciences solution suite. Each product is powerful on its own, but when used together they are even better.

Document Control software

Whether work / process instructions (SOPs), process descriptions, test specifications or other types of documents — you can create, revise and sign them all digitally with the document control software.

Training Management software

Extend the “Document Control” module to actively plan and record the qualifications of your employees with our training management software.

E‑learning software

Use the new software “E‑Learning” to train your employees digitally. Create an e‑learning course according to your wishes using Microsoft PowerPoint or integrate existing presentations.

Frequently asked questions (FAQs) about CAPA

Are there time limits for the execution of the process steps?

In the administration, time specifications can be entered for each process step. Reminder messages are sent before the process steps are due. The reminder message is sent to the processor of the task, the coordinator and the configured group that is to be informed about the reminder (for example, QA). A reminder is sent with the configured subject.

Can attachments be stored with a CAPA?

If additional files are required for a process, attachments can be uploaded in all process steps and linked to the current process. The attachments are stored under a corresponding document type in the DMS and can be viewed in CAPA under ‘Attachments’ by all process participants. You can configure which file types can be saved as attachments and how large the files can be.

Can a process be cancelled?

It can be configured so that the process can be cancelled at any process step. For the cancellation, it is required to indicate a reason in a mandatory field. Only the coordinator of the process is allowed to cancel.

Are there templates for measures in a CAPA?

Having entered a measure, you can save it as a template in the measure table. The templates are available for insertion in a CAPA. The due date for the measure is calculated based on the duration entered in the template.

Can process steps be subsequently corrected?

In principle, a process step is completed with an electronic signature and can no longer be corrected. With the function ‘Step back’ the process can be returned to a previous process step. The user who has completed this step receives it again for editing and the process continues from this step. Any return to a previous step is recorded in the audit trail.

Can tasks be delegated?

In all process steps that follow the initiation, you can forward the process step to another person. The recipient’s authorization is checked during the selection.

Can I analyze the CAPAs?

The essential data of a CAPA is transferred to the attributes of the data record. This allows you to search and analyze the CAPAs you have created. The analyses can be exported as PDF, EXCEL or WORD documents.

Can the predefined steps be customized?

The CAPA process flow has been designed in accordance with the GxP regulations and created in consultation with QM experts. Against the background of the validation documentation, the process steps are therefore mandatory. However, each process step contains a ‘Custom Panel’, which can be used to display further information or initiate actions.

Can the predefined designations be changed?

In the workflow administration, you can configure the names of the process steps, field names and datasets.

Are the contents of all process steps visible?

When working on a process step, only this step can be processed, but the other process steps are still visible.

Quick contact

Do you have a question about the CAPA module?

Our sales team will help you promptly and gladly.