QM software for your document & quality management » Digital LS

Modular. Holistic. Effective.

Your path to digitalization

Our digitalization solutions primarily address document-based processes in manufacturing, production and quality management. The ECM/DMS system can also be extended to include non-GxP applications and can be linked to your existing ERP system (e.g. SAP), thus enabling you to implement almost all document-based processes in your company.

DLS eDMS | eQMS — cloud or on-premise? Both!

In order to be able to offer you the ideal mode of operation for our software solutions, we are strategically aiming to give you, our customers, the choice.

We want you to be able to decide for yourself which deployment method is most suitable for your needs. In addition to the typical on-premise operation, in which the eDMS | eQMS Suite is operated in your own infrastructure, we offer you the use of our suite in the cloud as an alternative, either as software as a service (SaaS) or as an application service provider (ASP) in a state-of-the-art and secure data centre.

Our data centre partner is accessible to customers and interested parties and has many years of GxP know-how. As a matter of course, the data is stored and mirrored in Germany (Hamburg). The qualified data centre meets all current IT security standards and is distinguished by certifications and conformities such as ISO 27001, FDA 21 Part 11 Compliance, GxP Compliance and many more.

Get a compact short overview

Document Control software

Whether work / process instructions (SOPs), process descriptions, test specifications or other types of documents — you can create, revise and sign them all digitally with the document control software.

Training Management software

Extend the “Document Control” module to actively plan and record the qualifications of your employees with our training management software.

E‑learning software

Use the new software “E‑Learning” to train your employees digitally. Create an e‑learning course according to your wishes using Microsoft PowerPoint or integrate existing presentations.

Document Control software

Whether work / process instructions (SOPs), process descriptions, test specifications or other types of documents — you can create, revise and sign them all digitally with the document control software.

Training Management software

Extend the “Document Control” module to actively plan and record the qualifications of your employees with our training management software.

E‑learning software

Use the new software “E‑Learning” to train your employees digitally. Create an e‑learning course according to your wishes using Microsoft PowerPoint or integrate existing presentations.

QM process (Complaint | DC | CAPA | CC)

Digitalize your ISO processes. Control your production-related QM processes using digital workflows.

QM process (Complaint | DC | CAPA | CC)

Digitalize your ISO processes. Control your production-related QM processes using digital workflows.

Technical Documentation software

Create and update your technical documentation, e.g. in accordance with the requirements of the Medical Device Regulation (MDR).

Contract Management software

Keep track of your contracts. Let us remind you about key dates such as termination options or renewal options in a multi-stage procedure.

Technical Documentation software

Create and update your technical documentation, e.g. in accordance with the requirements of the Medical Device Regulation (MDR).

Contract Management software

Keep track of your contracts. Let us remind you about key dates such as termination options or renewal options in a multi-stage procedure.

Frequently asked questions (FAQ’s) about the quality management system

What are the specific requirements that GxP places on quality management?

As an answer, the German GMP regulations, AMWHV, help us: The quality management system (QM system) is a system that includes quality assurance, good manufacturing practice or good work practice, including quality control and periodic product quality review (PQR) (§ 2 Definitions).

§3 Quality management system, good manufacturing practice and good professional practice

Companies and facilities must implement a company quality management system (QM system) that corresponds to the type and scope of the activities performed. The QM system shall include good manufacturing practice in the cases referred to in paragraph 2 and good professional practice in the cases referred to in paragraph 3, and shall provide for the active participation of the management of the establishments and facilities and of the personnel of the various sectors concerned. All areas involved in establishing, maintaining and implementing the quality management system must have competent personnel and suitable and sufficient premises and equipment. The quality management system must be fully documented and its proper functioning demonstrated (§ 1).

For which industries does the introduction of a quality management system make sense?

Certified companies have long been the norm in manufacturing and industries with many production steps. However, it is also a fact that it’s increasingly used in the service sector. Managers have understood that process and “product” quality are also methods in this area to differentiate their own product from that of the competition. Furthermore, process quality is an effective way to avoid the cost of errors. That is why more and more companies in the service sector are relying on the DIN EN ISO 9001 quality management standard. The more specific the industry, the more specific the standard. For example, laboratories have an ISO 17025 system, the automotive industry has the IATF 16949 standard, and medical device manufacturers have the ISO 13485 standard. These exemplary standards are all derived from ISO 9001. However, due to their respective fields, they often have more extensive requirements and more specific bases.

What are the benefits of a quality management system?

A quality management system (QMS) has many advantages. It can lead to cost savings and facilitate market access. A quality management system helps companies in the following essential aspects:

- Improved market access: In a globalized market environment, a company with a certified QMS can demonstrate that quality and process safety are systematically addressed. In some industries, such as the automotive industry, such a certificate is a mandatory requirement for business transactions.

- Better quality at lower cost: Quality management ensures quality as early as possible in the development process. Early detection of defects is much more cost effective compared to detection during final inspection.

- Cost savings: The company saves money by producing less waste. This reduces the cost of purchasing raw materials and disposing of waste.

- Systematic quality thinking among employees: A QMS allows all employees of a company (not only the quality assurance experts) to be involved in quality assurance.

- Transparent business processes: Operational processes are documented and described. This makes them transparent and easier to review for improvement opportunities. It also makes it easier to identify and eliminate problems.

- Sustainable standard: Quality management systems help to secure the achieved optimizations in the long term by making the improved procedures and processes “standard practice” and thus the norm.

- Better know-how transfer: Documented and described workflows and processes enable a more efficient and effective transfer of operational know-how. This makes it easier to train new employees, for example.

What is QM software?

QM software (quality management software) automates the process of tracking and minimizing product deviations. Companies use these applications to monitor and control product quality. By collecting and analyzing data, companies can identify, isolate and correct unforeseen product defects or other problems that may occur during production. In addition, our QM software supports you in taking into account the relevant laws, guidelines as well as standards in the controlled environment, such as ISO 15189, 17025, 9001, 14001, 16949, FDA 21 CFR Part 11, MPG, ISO 13485, MDR 2017/745, and many more.

Where can our QM software support?

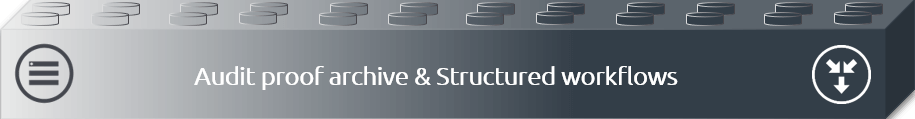

With the QM software from Digital Life Sciences, you receive a system at the highest level relying on the excellent process knowledge and expertise of the team. You get software that is open for the integration of other IT systems, such as LIMS/ERP. Due to the continuous further development as standard software, you are perfectly prepared with regard to the validation of the software and furthermore remain flexible with regard to your customization wishes due to individual configuration options. Moreover, our solutions can be understood as a modular building block system, where you can successively expand your system.

With the quality management software from Digital Life Sciences…

- you manage your default documents (e.g. work and process instructions, test specifications, hygiene plans), forms, contracts and other document types digitally

- you take care of document distribution and signature circulation digitally at the touch of a button and focus on your core business

- you protect your data from unwanted actions of unauthorized users

- save time by minimizing process runtimes for creating, revising, releasing, and distributing your default documents

- you reduce unnecessary printouts and paper on your desk. This spares the environment, your nerves and your money.

Does our QM software meet the requirements of an audit?

Our products were launched and validated successfully in numerous pharmaceutical companies. Likewise, our products have been successfully audited during TÜV audits in accordance with the guidelines of ISO standards 9001 and 13485 and during inspections by the Regional Council (Germany).

As a software provider for companies in the GxP environment, conducting supplier audits is common practice. In recent years, we have already been audited many times in on-site audits or postal audits by our customers and interested parties, e.g. in accordance with the requirements of GAMP5.

Quick contact

You have a question about our solutions?

Our sales team will help you promptly and gladly.